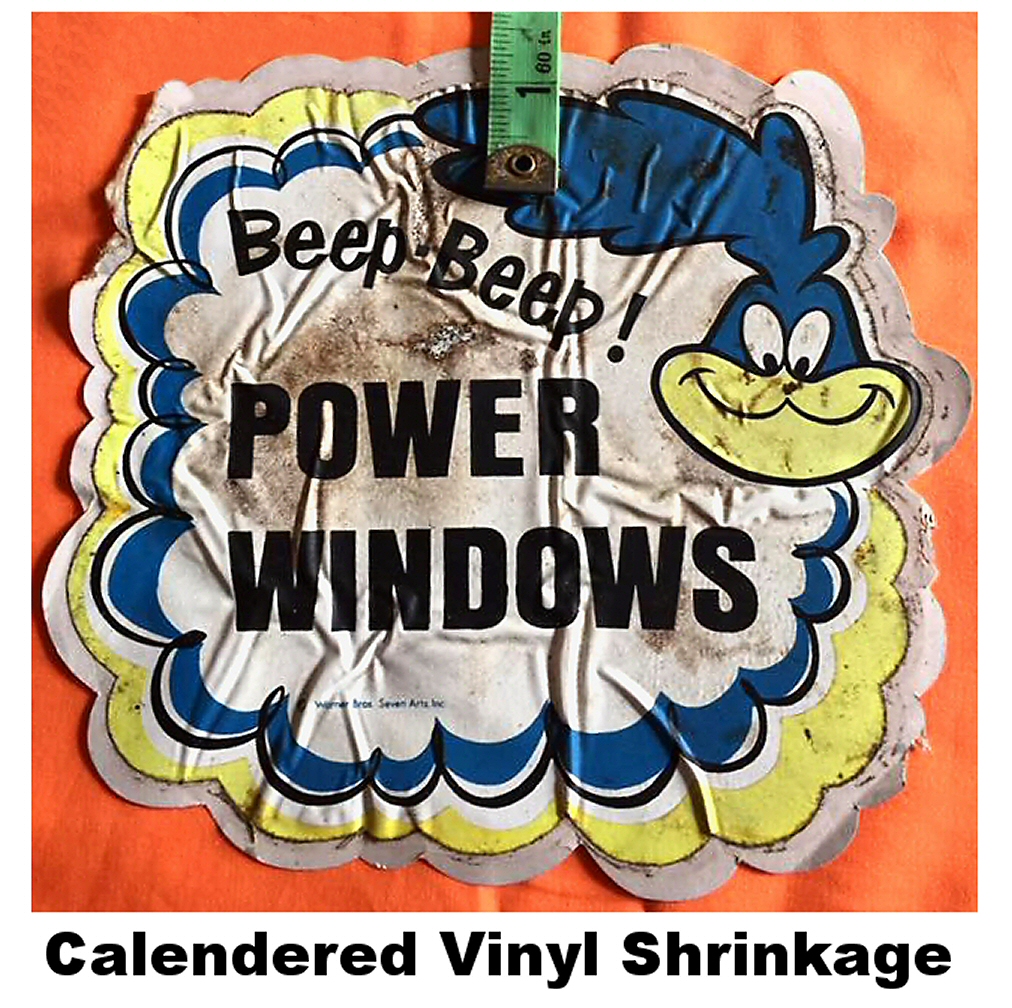

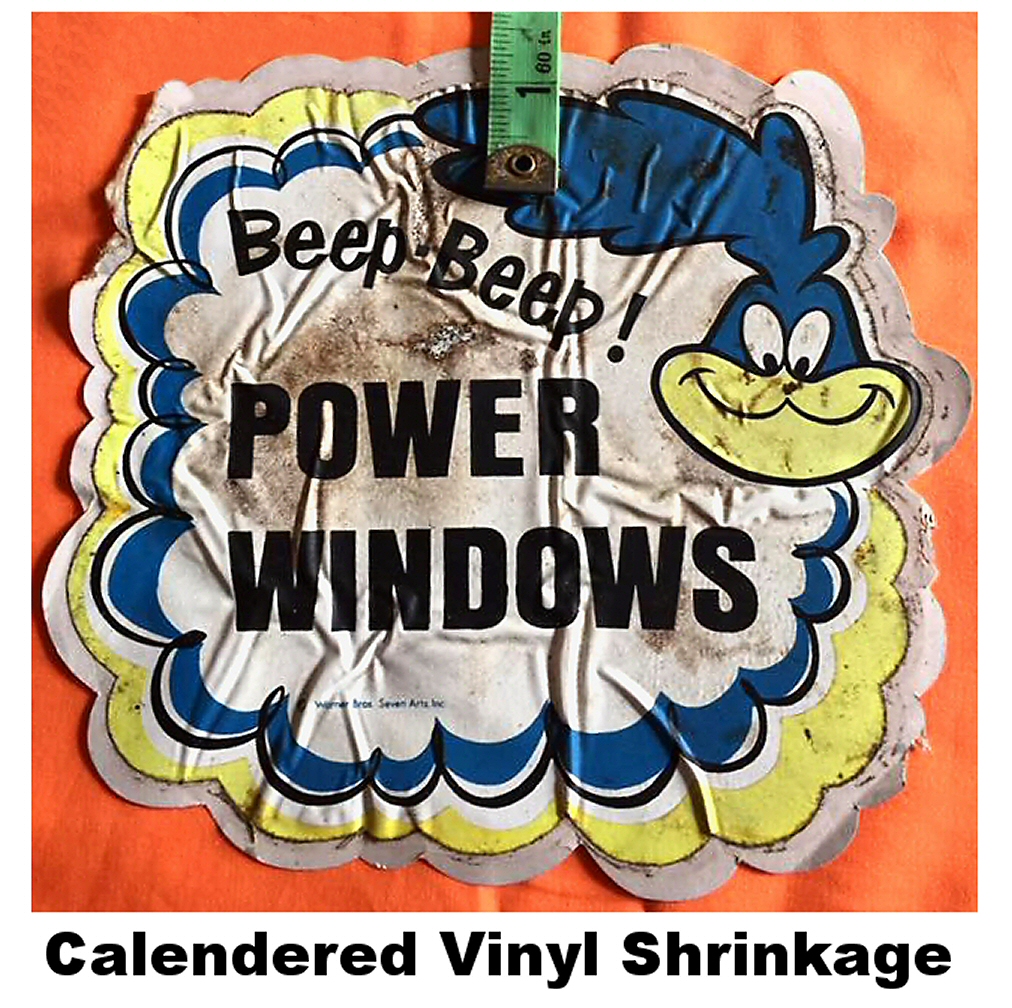

Cast vinyl is formed in a manner similar to pouring batter into a pan when baking a cake, while calendered vinyl is rolled out like pie dough. Cast film has the lowest shrinkage, cracking, and peeling of all vinyl films because the film itself has not had any stress applied to it during the manufacturing process, so it does not try to shrink back to or resume its original form. In contrast, calendered vinyl is squeezed through a series of rollers until it is the desired thickness, which causes it to “remember” its original form and want to return to it. Since calendered vinyl is meant for more temporary applications, cheaper raw materials are generally used in its production. Cast films can be made very thin, which produces a conformable product that allows application over substrates with curves. Cast films also maintain their color and other properties better than other vinyl films. Cast vinyl films with air-egress release liners have almost eliminated bubbles and wrinkles from applied graphics.

|

|